Co Design&Build

|

|

What is your role in the Papeteries Pichon project? We are providing project management for Papeteries Pichon. So, we have provided support from the start as technical advisers for the construction of the building up to launch of the automated process. How is the collaboration with the OpenBox teams going? In both design and construction, the OpenBox staff were highly attentive to our requests and they anticipated the process-related constraints from the design phase onwards, enabling the project to be completed smoothly and on time. Despite these constraints, OpenBox also created an elegant architectural style which is very appreciable for a company for which this will be the place of work. We also appreciated the responsiveness of our contacts. The operation evolved in a professional but very pleasant atmosphere. For you, how does Co Design&Build come to life? At this stage of the project, what stands out most are the concepts of transparency and dialogue: we had access to all the contractors’ quotes, which is not always the case. This enabled us to measure our negotiation leverage on global purchases and to arbitrate more easily regarding the execution of additional services. All necessary information was available and all choices and decisions were made through balanced dialogue. Was that a highlight of this project? The special feature of this project was the integration of an automated Savoye process. Throughout the project, we had to coordinate between the construction workers and the automation technicians, who did not necessarily take the same approach. This was all done in a cooperative manner, and even enabled us to get ahead of the schedule. OpenBox and Papeteries PICHON invited, on Thursday, March 28, the companions, elected officials and project partners to celebrate the progress of the construction of the new logistics base of Papeteries Pichon (Manutan Group) in Veauche, around the traditional "Gigot Bitume" . More than 100 people attended the event around Mr. Christian Sapy, Mayor of Veauche, Mr. Jean-Claude Schalk, Mayor of Andrézieux-Bouthéon, Mr. Guy Françon, Mayor of Saint-Bonnet-les-Oules, Mr. Thierry Cappé, Managing Director of Papeteries Pichon and Bertrand Chabanne, President of OpenBox. Guests saw a cell of 12000 m² (one of the first in France) that will house a Magmatic, as well as offices, bathed in natural light. Thierry Cappé and Bertrand Chabanne pointed out the effectiveness of the Co Design & Build method, which has been guiding teams from the beginning and has establish relationships of trust and effective collaboration.

Architect XXL Workshop / AMO: ETYO / Automation: SAVOYE See the reference sheet Papeteries Pichon (Manutan Group) decided to construct their new logistics platform on the Forez plain and the operation was monitored by Loïc Thomas, project manager.

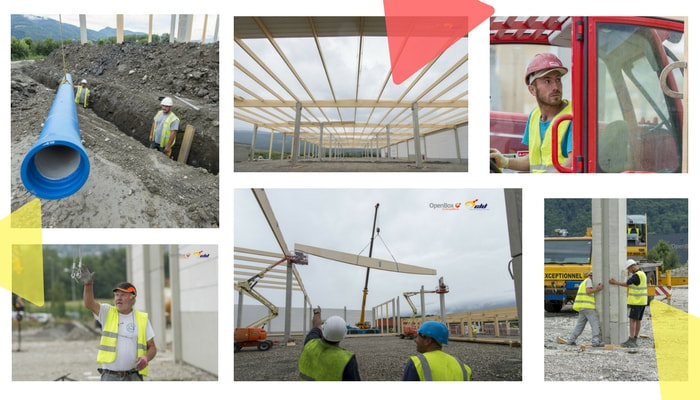

OpenBox designed and executed this project: 21,600 m² of fully automated warehouse space and high-quality offices. A new Decree, published in April 2017, allows the surface area of storage units to be doubled to 12,000 m², whereas until now it had been capped at 6,000 m². The building will double the order processing capacity of Papeteries Pichon, which is growing rapidly. We are currently raising the superstructure of the building. The slab will be poured at the beginning of 2019. This step is particularly important for the success of the operation as it is the main interface with the automated process. The structures supporting the various logistic areas are extremely sensitive to changes in position. The tolerance levels are in the order of a millimetre and have required the deployment of a finite element model in order to predict the differential settlement under each of the supports. From the beginning of the project, the staff from OpenBox, Etyo (Project Management Assistance), Savoye and Papeteries Pichon worked together using the Co Design&Build method: regular meetings and the co-creation of solutions taking into account the technical, architectural, logistical, environmental and security constraints, as well as the transparency of procurement prices. Special attention was paid to the architectural quality of the buildings, including the offices and common areas, in order to meet the requirements of the Manutan Group, winner of the “Best Workplaces France” label. The layout of the roadway to the offices enhances one’s arrival the site: there are walkways, a treated water retention pond on landscaped grounds, a covered gallery and common entrance for the offices and warehouses located at the rear. The architects, XXL Atelier, also designed the building to have interior patios bathed in natural light. The ergonomics, the choice of materials, the treatment of façades, the landscaped areas, everything has been designed to highlight the building and warehouses. Construction using Co Design&Build will ultimately enable the difference between the price agreed in the contract and actual costs on the basis of certified accounting to be shared. Why did you choose OpenBox?

Our project was strategic: there were challenges involving time, business continuity, installation... We had already managed one property project, but we did not have all the resources needed to succeed by ourselves. OpenBox provided us with support at a very early stage. However, we also conducted a competitive bidding process in order to obtain the best proposal. Their experience and knowledge of the regional eco-system, their prices and their motivation made all the difference. Regarding the project, they were available and ready to listen, they put forward the best solutions. Their obvious knowledge of logistics and its constraints is reassuring. What's more, it's a small, dynamic and innovative company. We were attracted by their way of working and their mindset. We are proud today to have helped them to grow. How did the collaboration with the OpenBox teams go? We never doubted their professionalism. They are experienced and know how to find the right people. They are also very attentive and have handles our requests, even the last-minute ones. They use a model that enables this to happen. We felt we were supported before, during and on delivery of the project. Despite the difficulties associated with their profession, I believe they always have the desire to satisfy their customers. How did the delivery process go? Delivery is always a delicate moment. We quickly realized that OpenBox shared, as we do, the desire to maintain a steady pace and to remove any reservations as quickly as possible. They remained highly available during the acceptance period and they resolved problems as they arose. What does Co Design&Build mean for you? We had to ask OpenBox to adapt their proposal, which they agreed to very quickly. They were very transparent, especially regarding costs over the entire project, and changes were far easier to manage. OpenBox has also collaborated with numerous stakeholders with a great deal of integrity (three project management assistants, a developer and an investor). Regarding the sharing of savings, as commonly happens with Co Design&Build, we preferred not to consider this alternative during the competitive bidding stage. We only addressed this proposal after selection. They agreed to pay €60,000 for renovations to our old platform. This is a kind of variation on the sharing of savings offered by Co Design&Build. You have been in your new building for a few months now. Are you happy with it? Everyone is happy with our new working environment. As part of the acquisition of Transports Charvin by BBL INVEST, it was a question of successfully accommodating four of the group’s companies at the same site and making people comfortable there. We wanted a high quality, well thought-out building: the choice of materials, the architecture, the services and the organisation of the building are all elements that have created a great logistics platform to work at! Last July, OpenBox and DCB Logistics thanked the project’s partners and associates around a traditional ‘gigot-bitume’ [leg of lamb wrapped in kraft paper and cooked in molten bitumen]. This new 23,000 m² temperature-controlled warehouse (+15°C / +18°C), which was completed at the end of July, is dedicated to food product storage, order preparation, co-packing and transportation. 3 cells were built, a fourth remaining as a further extension. OpenBox’s expertise on this type of logistics platform enabled the challenges of this complex project to be addressed with all of the stakeholders. More information on the project. Gilles Saubier, Groupe STEF, Dominique Berger, Vaulx-Milieu, Bertrand Chabanne, OpenBox, Didier Caudard-Breille, CEO DCB International, Jean-Marc Portanguen & Laurent SEVEN, DCB Logistics, Hugues Golzio, CEO BEG Ingénierie

Crédit photos: Groupe DCB International et Béatrice Bocquet Construction workers continue to make progress on the GLD site despite the heatwave. Tune in next September for the latest instalment of the "Co Design&Build" journey.

A look at the collaboration between OpenBox and GLD with Pascal Dominois, Director of Operations at GLD

Why did you choose OpenBox? When consultation began at the beginning of 2016, it seemed to us that OpenBox, as a company, was too young and was not, therefore, a credible option for us. But OpenBox insisted on delivering an offer, they were extremely motivated! For our part, we wanted to assess the proposal of the contractor with whom we were already working. We were surprised by the gap between both prices. The determination of the team, indeed its obligation to succeed in the operation, convinced us. We decided to trust them. And we have no regrets! How would you describe your experience with Co Design&Build? The Co Design&Build meetings were very reassuring and they enabled us to move forward with the project together as a whole. Reports on accounting, planning, costs, everything was reviewed each month. A completely different way of working. We were able to see that the OpenBox strategy didn’t involve margin recovery but was more concerned with information sharing and collaboration. When issues arose (which inevitably occur on such projects), they were discussed and resolved. Everything was done progressively as we moved forward, in a collaborative way. When you don’t discover things too late, you can’t suspect a hidden agenda. So tensions are quickly dissipated. Given the highly competitive circumstances and the consensual efforts made during the negotiation, the “shared savings” at the end of the operation were limited, but the transparency was a reality that made the offer unique. Objectively, this transparency and collaboration allowed us to conduct this operation in a relaxed and constructive way, until the snagging list was resolved. Throughout the entire project, we felt supported. Are you satisfied? Of course, because the timing and the price were kept in check and the building is consistent with what we wanted! Our new 24,000 m² tool means we can work with large industrial clients, who are careful about the handling of their goods (like Rolls-Royce Civil Nuclear, Hager, etc.). We offer them tailored solutions for storage, procurement, industrial packaging and transportation. Whatever the sector (pharmaceutical, food, energy, mass distribution), our expertise in logistics and our set-up are the hallmark of our reputation, but our warehouses are a definite advantage: now when we tour the warehouses with our clients, the design quality wins them over. The building is also scalable, as demonstrated by the 25-tonne-capacity overhead travelling crane, which are already being installed for our industrial packing and handling operations for large volumes. We will therefore be able to offer integrated solutions under the same roof, in a high-end environment. Progress advances at the DeguiseToi.fr e-commerce logistics platform in Vaulx-Milieu in a spirit of collaboration and transparency. Friday 19 May: Jadéo, OpenBox, their partners and construction workers celebrate progress at the site. More information.  In early 2017, OpenBox constructed warehouses extending over an area of 24,000 m² on behalf of GLD, a leading logistics provider in the French city of Grenoble. Pascal Dominois, operations manager at GLD, selected OpenBox because of their pricing and their unique advantages. What are your goals for this commercial real estate project? Our core client base is predominantly made up of large industrial companies based in the greater Grenoble area. In this region, real estate is a scarce resource that can jeopardise the performance of the entire supply chain. This shortage of available land for building has led to a dearth of modern logistics facilities, which play an essential role in the development of local economic activity and the creation of employment. Next-generation logistics platforms facilitate freight consolidation within transport hubs, reducing the financial and environmental cost of transportation. Moreover, having such a platform at our disposal will allow us to expand our logistics, transport and industrial packaging services within an infrastructure that is capable of meeting the demands of even the most challenging business sectors. By locating this new platform in close proximity to the greater Grenoble area, we are consolidating our position as a regional market leader and can offer our existing and prospective customers a viable, flexible and high-quality solution. Our logistics hub, extending over a single 60,000 m² site, is the only one of its kind in Grenoble. This hub is vital for us as a means of achieving our growth objectives; it's vital for our customers as a means of securing their long-term future in the region; and it's vital for greater Grenoble as a whole as a means of increasing and securing employment opportunities. In your opinion, how does the "Co Design&Build" offering differ from the other design and construction solutions on the market? From the first point of contact, we felt that we were dealing with a clear, transparent offering. As we were satisfied with the result of a previous construction project completed with the help of a general contractor, we did not want to invest time in providing a detailed description of our requirements followed by a thorough assessment of proposals. The collaborative process allowed us to make sure that we would quickly come to an agreement on the type of building to be constructed. With the "Co Design&Build" model, we can easily access key information whenever we need it, including the technical solutions proposed and implemented to meet our needs, the firm performance obligations we have agreed on, the list of companies that took part in the tendering process, and the current status of the schedule. Knowing the actual building costs and sharing any savings achieved also brings significant benefits in terms of reducing our own costs. Why did you select OpenBox for your project? In all honesty, and despite the numerous advantages offered by the "Co Design&Build" model, our original intention was to renew our partnership with the general contractor that we had worked with previously. However, OpenBox's competitive offering and extensive expertise led us to reconsider our decision within a few short weeks. Given the solution's solid technical, legal and financial credentials, it made no sense not to opt for the benefits of a solution that was more transparent, collaborative and cost-effective. For more information on this project, go to "Collaboration in action  This e-commerce pure player was won over by OpenBox's offering. Sylvain Ferreira, CEO of parent company Jadéo, explains why he decided to entrust his distribution centre project to OpenBox, and describes the way in which he collaborates with our teams. What are your goals for this commercial real estate project? As a pure player in the e-commerce sector, logistics has always had a strategic focus for Jadéo – it's one of the cornerstones underpinning customer satisfaction. For this reason, we had never even considered outsourcing logistics before, because it's of such vital importance to our company. Similarly, we felt it was important to retain control of our real estate to ensure that it was optimally adapted to both our business sector and our growth targets. Since starting the project, there has been an increase in the scope of our business and in our sales volumes, due in particular to an acquisition in Germany. Our new platform will handle all despatches in Europe. In your opinion, how does the "Co Design&Build" offering differ from the other design and construction solutions on the market? Before now, we had never been involved in managing construction projects. Therefore, our first task was to gain an understanding of the different offerings in the sector, the positioning of the various market players and the potential solutions available. Again, we wanted to retain full control of all information and decisions. For this reason, we invested a lot of time in the tendering phase. I should mention that we were approached by a large number of companies. Several of them tried to impose their own schedule and conditions on us, based on their knowledge of the market, the legislation, the other players, etc... The "Co Design&Build" proposal was different to all the other proposals we received. The OpenBox team was on our side from the word go, and we held all the cards when it came to decision-making. They provided us with all of the information available to them, including details of the technical solutions and their pricing – but also the actual costs involved. Building our working relationship on this basis meant that all of the key steps in the process were carried out in a spirit of constructive dialogue. We have now adopted a project-based approach, with everyone pulling together, especially during "Co Design&Build" meetings where we are updated on company pricing, technical alternatives, works contracts, expected savings, etc. Nonetheless, our relationship is clear: we are the customer, and OpenBox are bound by certain performance obligations as specified in the real-estate development contract. Why did you select OpenBox for your project? The relationship of trust was built up gradually in the tendering phase. OpenBox understood our requirements perfectly and proposed solutions that were tailored to our needs. As they were a young company, however, we at first assigned them a project management assistance task so that we could gauge the quality of their work. During this phase, we had the opportunity to witness their commitment and their ability to protect our interests. When we compared them with general contractors, the "Co Design&Build" model proved considerably more competitive yet provided the same guarantees. As we were very impressed with OpenBox's working methods and collaborative approach, the choice was obvious. For more information on this project, go to : Collaboration in action |

Catégories

All

Archives

January 2024

|

RSS Feed

RSS Feed